A chronology of cloth mask construction during COVID.

Do you notice that Nancy Pelosi’s mask sucks in annoyingly when she is making an important speech (must drive her nuts!), when hospital drama medical staff casually remove their masks multiple times in as many minutes, or when TV interviewers wear their masks covering their mouths but not their noses?

If anyone had predicted a year ago that I would be obsessed with facemasks, I would not have believed it, yet, here I am, up to my eyeballs in mask-making, working hard on perfecting patterns, and learning about the best materials to ensure they are as safe as possible.

Early in the COVID pandemic, a local care agency asked our quilt guild to make masks for their staff and clients, and provided their preferred pattern. Guild members quickly took up the challenge and produced hundreds of masks, safely delivered in baggies to a drop-off box on a member’s front porch.

This mask design had three pleats and a filter pocket, which opened along the bottom edge of the mask. We used doubled craft pipe cleaners for nose wires and whatever elastic we could get our hands on for ear loops. Filters? Well, I bought a furnace filter, tore it apart and cut it into mask filters. I was not a fan of the mask pattern, however, as there were too many layers to sew through on the pleats, and it was very fiddly to insert a filter into the pleated space through the single opening. I was also concerned that the mask sucked in and touched the mouth when talking (in scientific terms this is called “indrawing”).

Other local agencies began asking for masks as well, but were not specific about the design, so I searched the internet for a more maker-friendly pattern and better information. Over the next few months I tried multiple patterns and learned and pondered all sorts of things:

- A better fit under the chin is important.

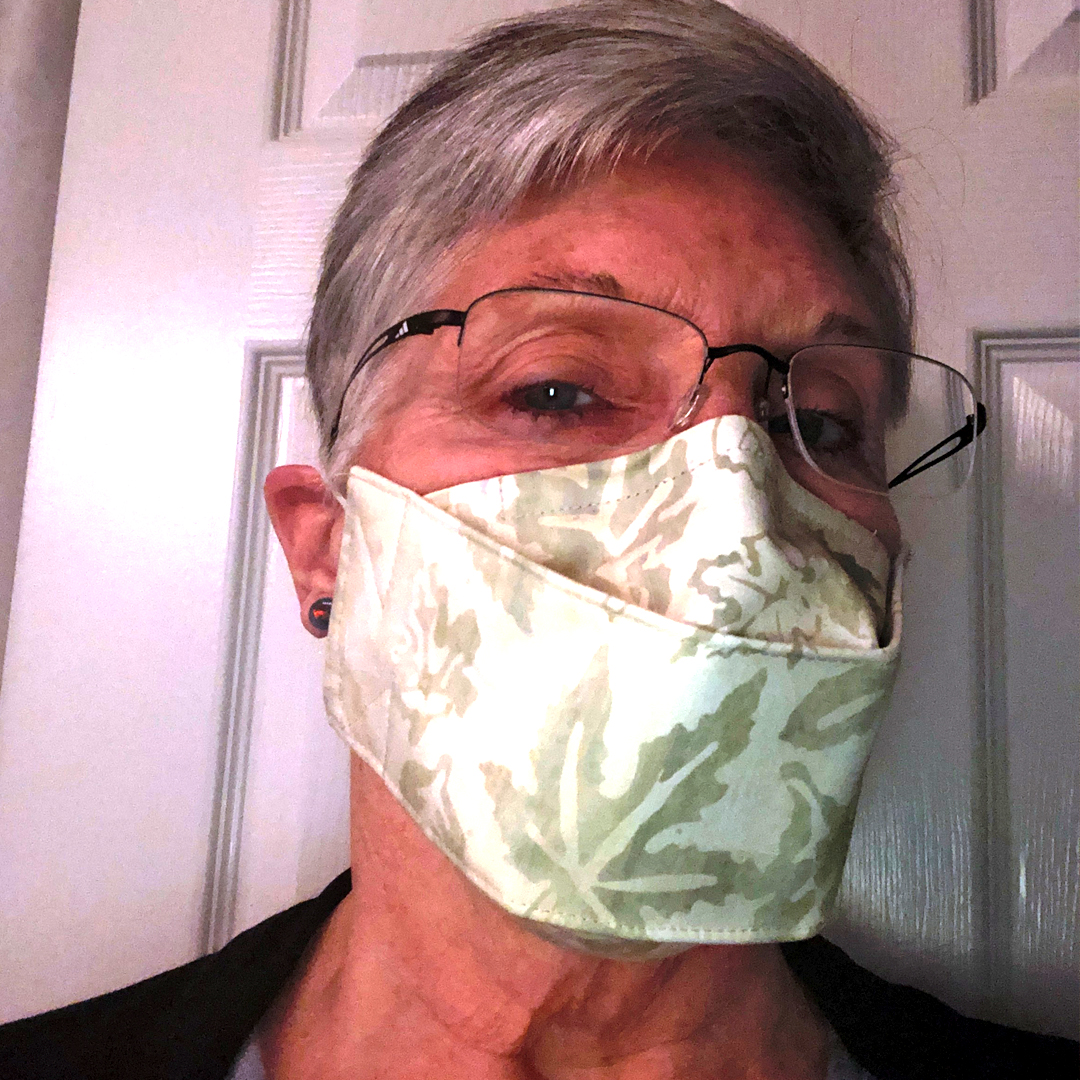

- The biggest complaint is fogging glasses…better nose pieces and patterns needed.

- Some masks gaped at the sides where the ear loops attached.

- Some masks used complicated templates.

- Two layers of batik may not be as breathable as quilter’s cotton…is one better than the other? What about the waxes in the batik?

- I tried disposable industrial blue towels as filters, and wait – could flannel be used as a filter?

- Removable filters are easier to insert in mask with two openings, but openings on the sides of the mask tend to be narrower than the centre, so positioning is still tricky and time-consuming.

- Most clients of the agencies we were providing masks for were not using filters anyways.

- There were concerns about masks with centre seams…does the virus flow through needle-punched holes?

- Is machine washing better than hand washing?

My online searches led me to an excellent article, based on a peer reviewed publication, from the Centre for Excellence for Protective Equipment and Materials (CEPEM) at McMaster university: COVID-19 masks FAQs: How can cloth stop a tiny virus? What’s the best fabric? Do they protect the wearer?

This article confirmed that I was on the right track…that any mask is better than no mask and has benefits to both the wearer and the public. I contacted CEPEM and began a correspondence, which resulted in an invitation to join the Cloth Mask Knowledge Exchange (CMKE), a diverse group of manufacturers, designers, users, and scientists, which has input into, and shares information from, the cloth mask research ongoing at McMaster. I am proudly serving as the Canadian Quilters Association (CQA/ACC) Liaison to this committee.

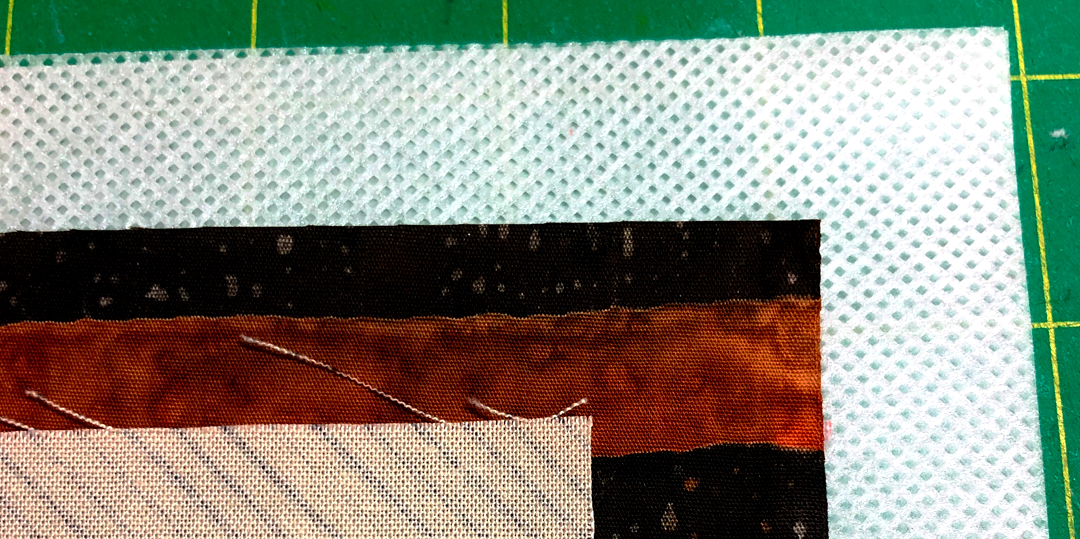

Since I have been serving on the CMKE, Health Canada announced a recommendation for the use of non-woven spunbond polypropylene as the preferred filter material in cloth masks. Mask-makers had so many questions about this material and its availability, and the researchers quickly provided answers in another article: Polypropylene, the material now recommended for COVID-19 mask filters: What it is, where to get it.

Following this publication, I dove into a project to find at least one supplier of polypropylene in each province, which involved a huge internet search and grappling with Excel spreadsheets. This Sellers List is now available on the website, a great resource for makers of cloth masks. All sellers of polypropylene are invited to fill out the linked questionnaire to have their contact information included on the list.

I am now using a layer of 70 grams/square metre (2 – 2.25oz/sq. yard*) spunbond polypropylene in all my masks and am replacing all previous versions provided to family and friends. I feel I am moving forward with the science, but there are still many outstanding questions, such as: Does washing masks alter the fabric or polypropylene to be less effective over time? How often should a cloth mask be replaced? What is the best fabric to use for masks? What is the best-fitting mask design?

Fortunately, the research group at McMaster is also contemplating these issues and is working hard to provide answers. “Flat testing” of many different fabrics was undertaken in the lab, and a research paper will provide those findings following peer review. Shortly another phase of testing will begin to evaluate the fit of different mask designs, each made of the same materials.

Stay tuned to the Cloth Masks website and future CQA/ACC publications to learn more when these results are available.

Note: It is difficult to source the 2.0 or 2.25 oz polypropylene. Many sellers carry a lighter version: 1.0 or 1.5 oz., so I just put in two layers.